Towards computer vision feedback for enhanced CNC machining

Por um escritor misterioso

Last updated 25 abril 2025

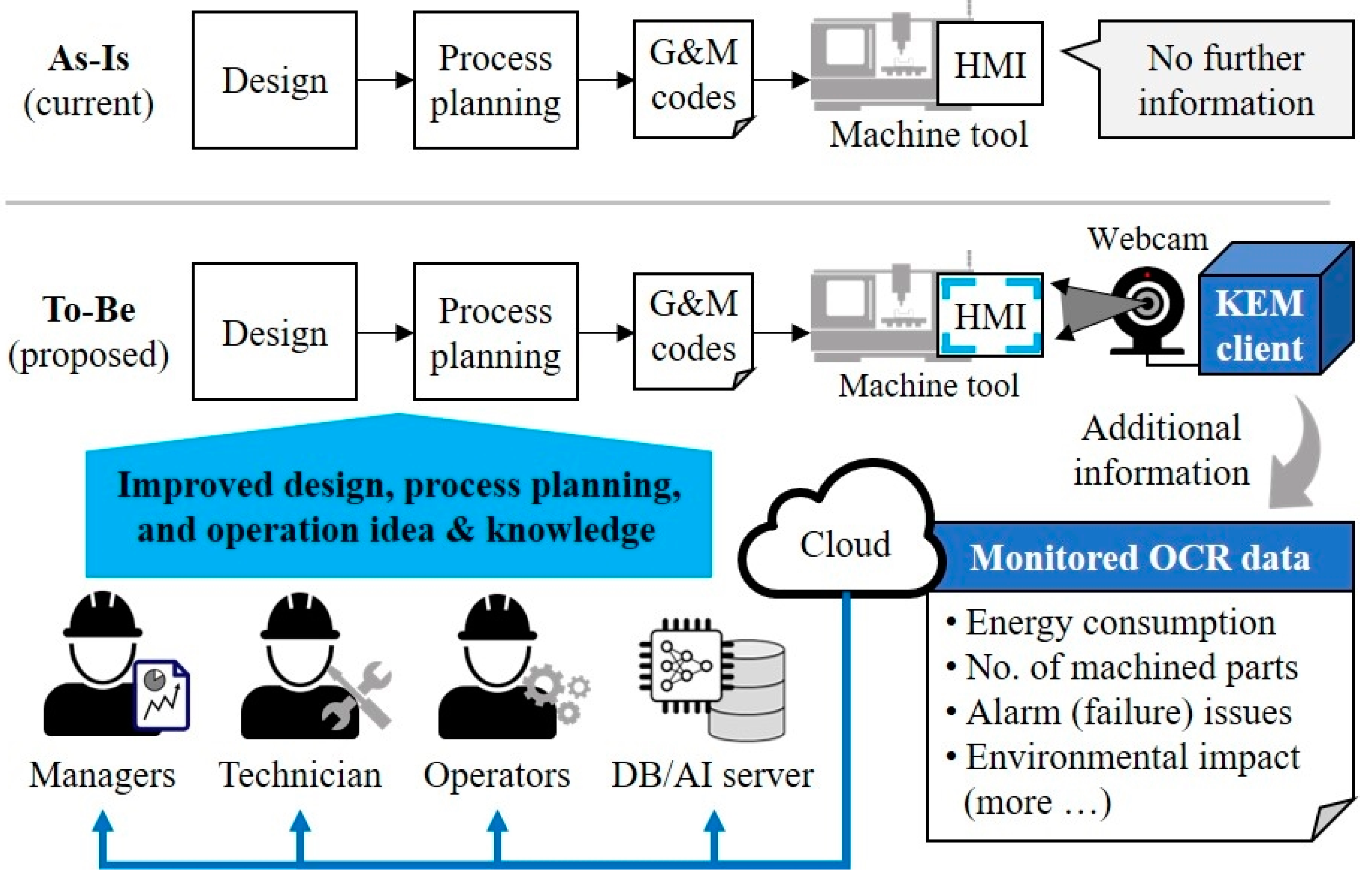

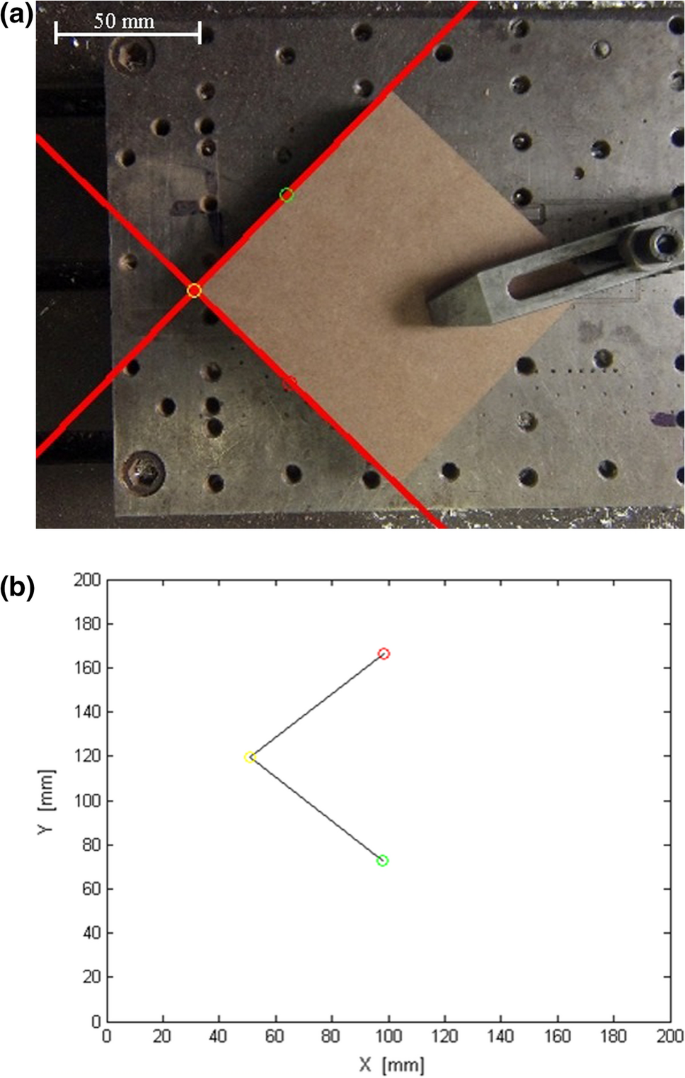

A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines and to facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file to enable real time integration of the gained feedback information. A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines. Two cameras are attached to the machine spindle to provide visual information on work-piece surface quality while machining. This information is processed and processing outcome is used to improve the surface roughness of the machined part by adjusting the employed machining parameters. To facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file in order to enable real time integration of the gained feedback information. The manipulated G-code program is then executed by the machine controller to allow adaptive control of the work-piece machining. The developed system automatically determines which camera is required to provide scene data for each step of tool path movement. Relative camera is then activated just as the machine completes the cutting of each tool path segment. Acquired vision data is processed to evaluate resulting surface roughness and accordingly a decision is made to either maintain the implied machining parameters or adjust their values to beneficially suit the machining task and result in better surface quality. The developed approach is tested and verified experimentally. Promising results are acquired that encourage further development towards full integration of CNC-vision systems.

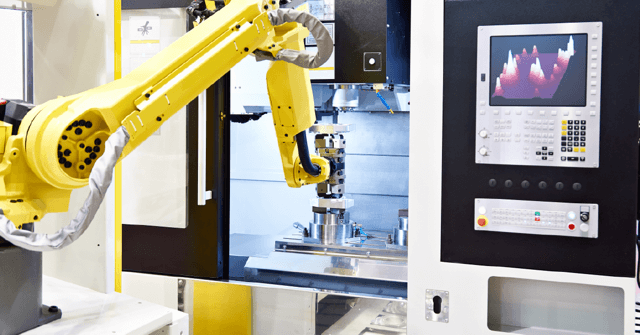

Using artificial intelligence to control digital manufacturing

Machine learning and artificial intelligence in CNC machine tools

Sensors, Free Full-Text

Machine Shop Excellence

A critical review for machining positioning based on computer

Towards computer vision feedback for enhanced CNC machining

CNC Robotics: Top 5 Tips for Using Machining Robotics in a CNC

Towards computer vision feedback for enhanced CNC machining

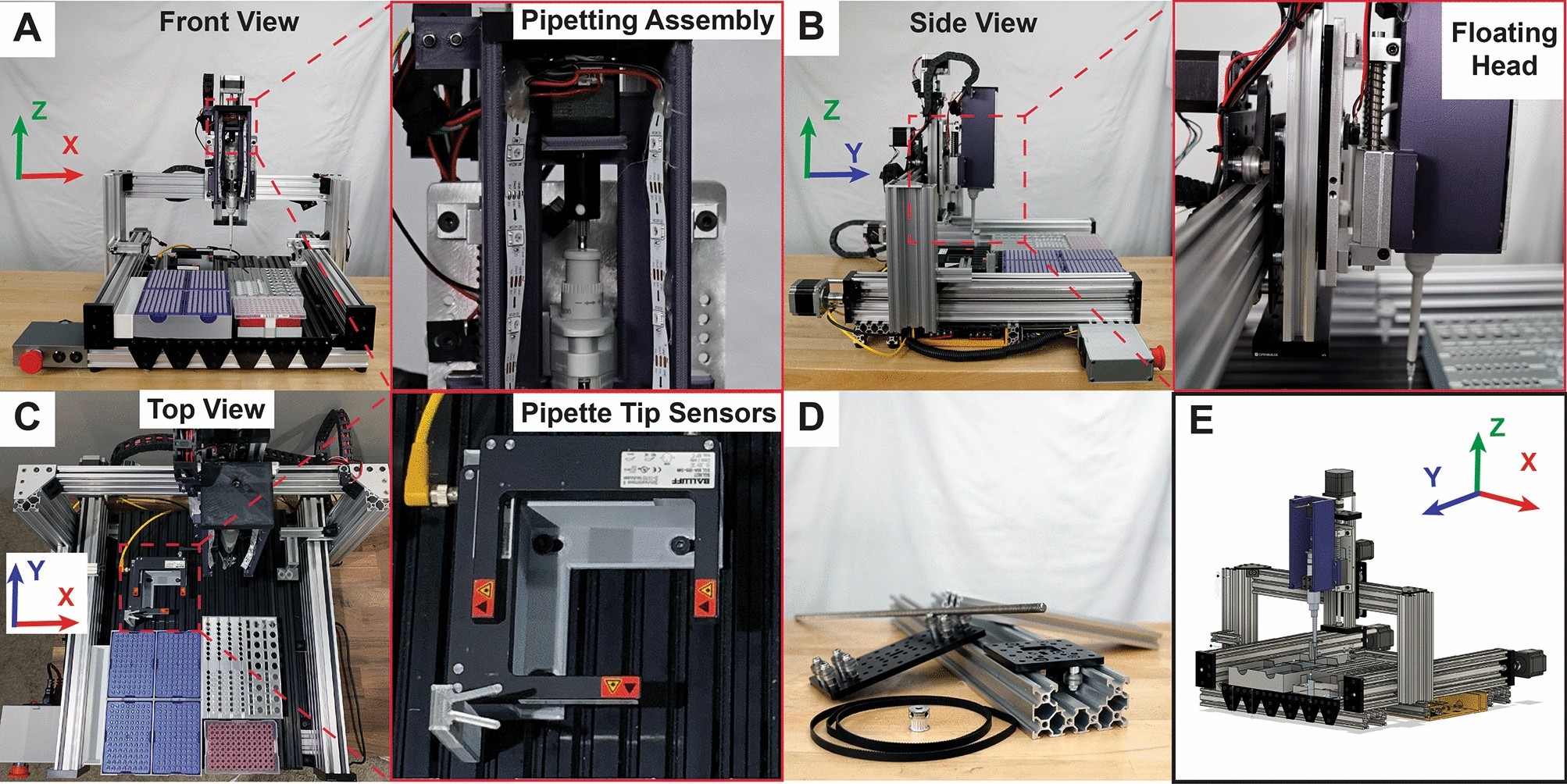

Principles of computer-controlled linear motion applied to an open

Machine learning and artificial intelligence in CNC machine tools

ABB launches breakthrough robot alignment software increasing

Sensors, Free Full-Text

Development of a computer vision-based system for part referencing

Machine tool automation: What it is and why it's needed - HEIDENHAIN

Recomendado para você

-

3 Row Radiator For 1966-79 Ford Bronco Truck F100 F150 F250 F35025 abril 2025

3 Row Radiator For 1966-79 Ford Bronco Truck F100 F150 F250 F35025 abril 2025 -

322127-G1 AVS Aeroskin Color Match Bug Deflector - Fits 2017-201925 abril 2025

322127-G1 AVS Aeroskin Color Match Bug Deflector - Fits 2017-201925 abril 2025 -

The GCode section - Troubleshooting (X35/X50) - Onefinity CNC Forum25 abril 2025

The GCode section - Troubleshooting (X35/X50) - Onefinity CNC Forum25 abril 2025 -

:strip_icc()/i.s3.glbimg.com/v1/AUTH_59edd422c0c84a879bd37670ae4f538a/internal_photos/bs/2022/0/y/AuIf32Tv6B9oGxf6dWBQ/carro-antigo.png) Colecionador de carros antigos em MT tem modelos fabricados há25 abril 2025

Colecionador de carros antigos em MT tem modelos fabricados há25 abril 2025 -

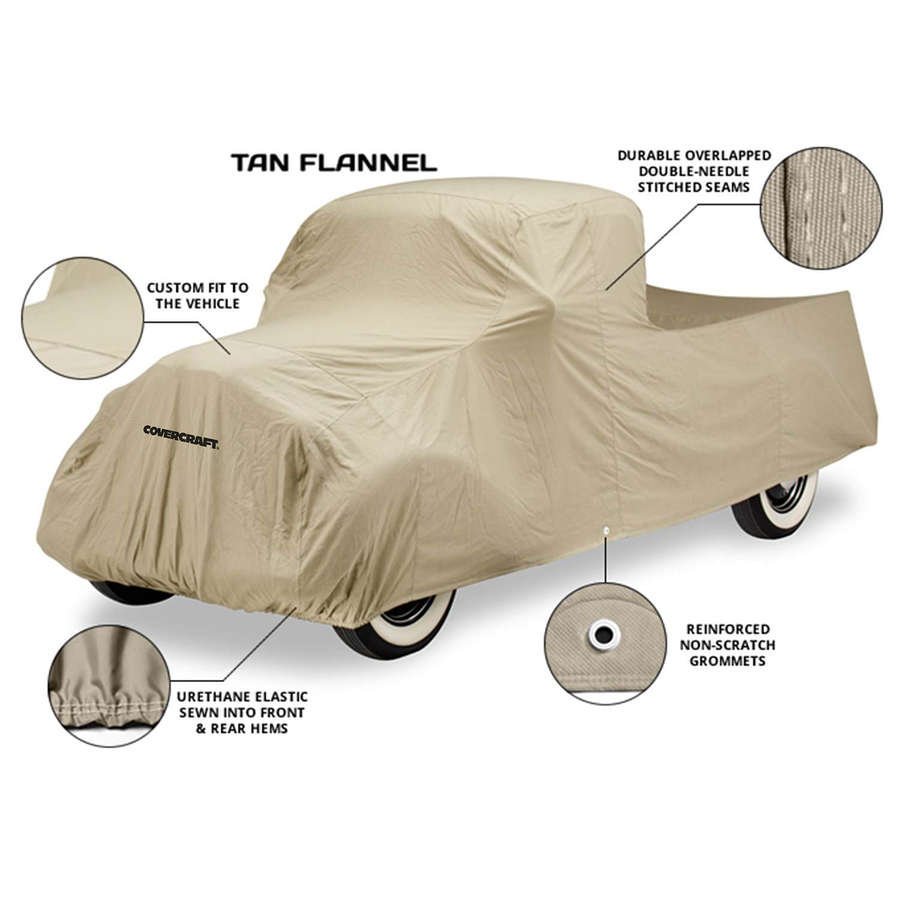

1st Gen Camaro Tan Flannel Indoor Car Cover25 abril 2025

1st Gen Camaro Tan Flannel Indoor Car Cover25 abril 2025 -

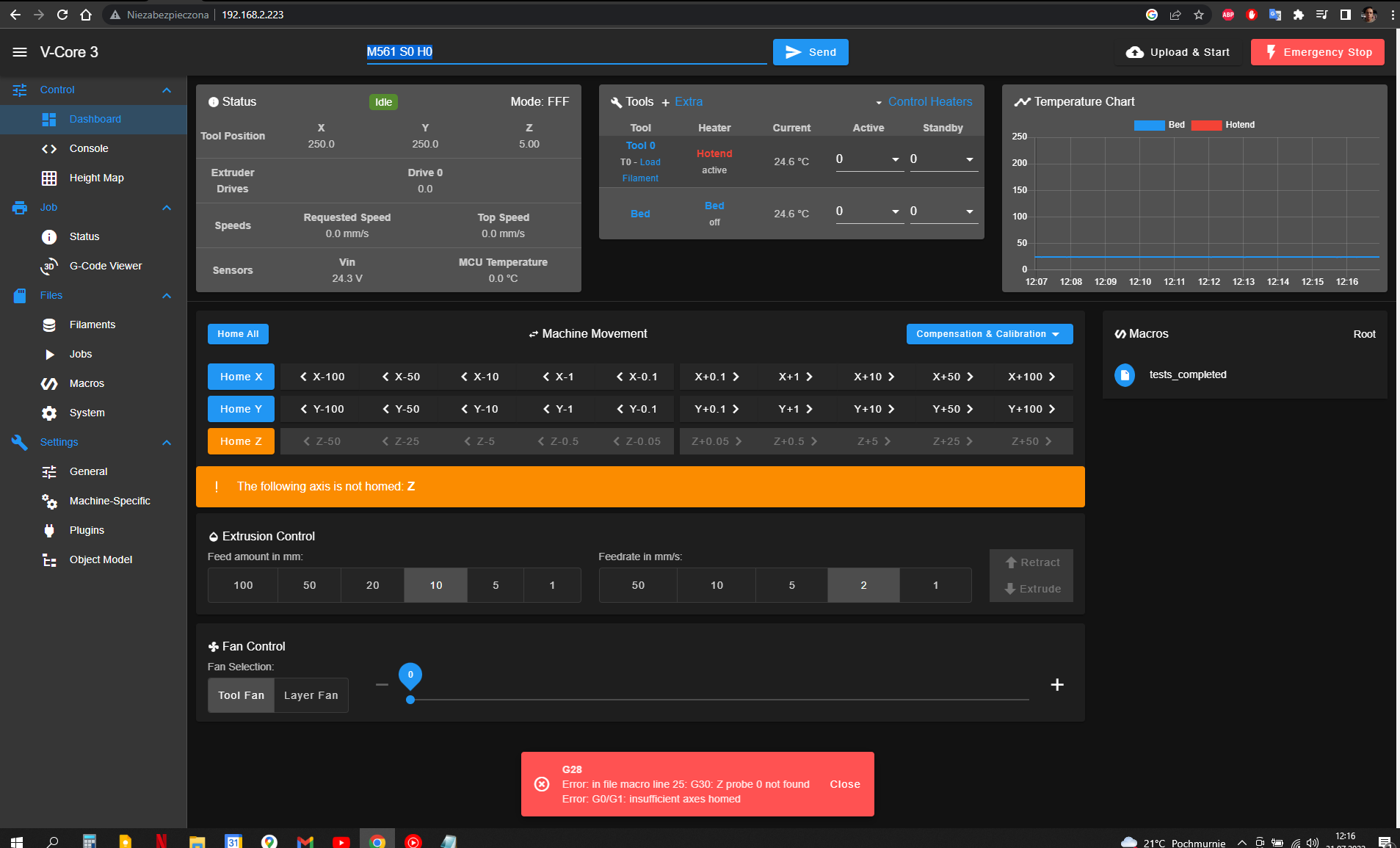

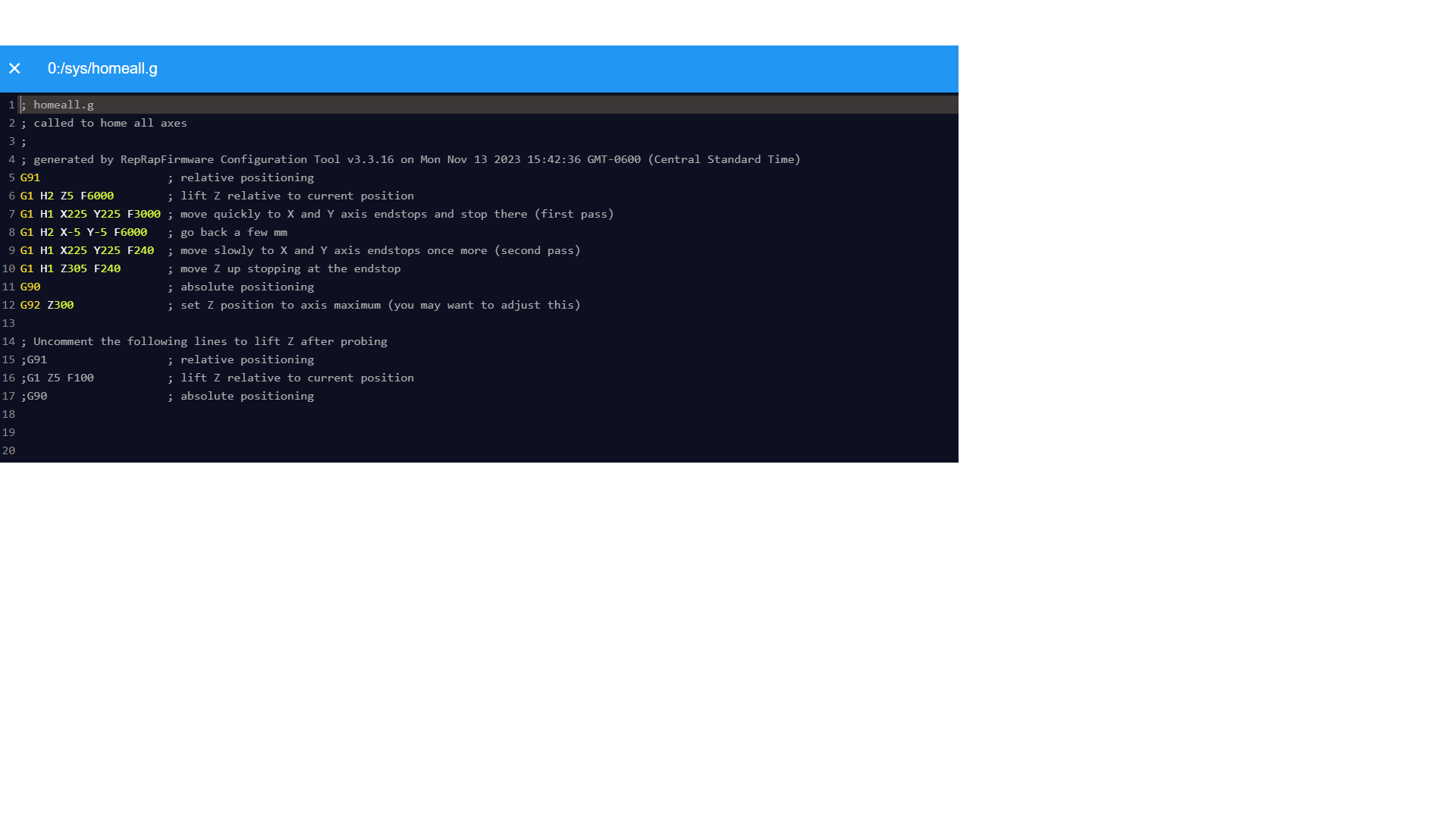

error G0\G1 home Z ratrig vcore 50025 abril 2025

error G0\G1 home Z ratrig vcore 50025 abril 2025 -

Used ABB Robot HGR Industrial Surplus25 abril 2025

-

BL touch bed lowering till bl touch errors out from not touching25 abril 2025

BL touch bed lowering till bl touch errors out from not touching25 abril 2025 -

Complete Manual Transmissions for Ford F-10025 abril 2025

Complete Manual Transmissions for Ford F-10025 abril 2025 -

F-100D SUPER SABRE 90MM EDF SUPER PNP – Flex Innovations25 abril 2025

F-100D SUPER SABRE 90MM EDF SUPER PNP – Flex Innovations25 abril 2025

você pode gostar

-

Hm1298 2018 Mozambique Bobby Fischer Carlsen Kasparov Chess #955425 abril 2025

Hm1298 2018 Mozambique Bobby Fischer Carlsen Kasparov Chess #955425 abril 2025 -

Idlewild Baptist Church gives $38,000 to forgive student lunch debt accumulated during COVID-19 - Florida Baptist Convention25 abril 2025

Idlewild Baptist Church gives $38,000 to forgive student lunch debt accumulated during COVID-19 - Florida Baptist Convention25 abril 2025 -

Blue Lock 23925 abril 2025

Blue Lock 23925 abril 2025 -

STL file Guile from Street Fighter 👤・3D printing design to25 abril 2025

STL file Guile from Street Fighter 👤・3D printing design to25 abril 2025 -

Glitch Arcade25 abril 2025

-

Get Zombs Royale - Microsoft Store25 abril 2025

-

Que responsa! Aos 17 anos, Lorde será responsável por toda a trilha sonora do novo Jogos Vorazes - Pop - R7 Jovem25 abril 2025

-

Assistir Isekai de Cheat Skill wo Te ni Shita Ore wa Episódio 1225 abril 2025

Assistir Isekai de Cheat Skill wo Te ni Shita Ore wa Episódio 1225 abril 2025 -

Clifford the big red dog. Celebrate with Clifford - NOBLE (All Libraries)25 abril 2025

-

TOP 10 JOGOS DE DRIFT PARA CELULAR PART 225 abril 2025

TOP 10 JOGOS DE DRIFT PARA CELULAR PART 225 abril 2025