UNDERSTANDING POROSITY FORMATION AND PREVENTION WHEN WELDING

Por um escritor misterioso

Last updated 25 abril 2025

Keyhole laser welding is a joining technology characterised by the high focussed power density applied to the workpiece, facilitating deep penetration at high processing speeds. High aspect-ratio welds produced using this process invariably have narrow heat-affected-zones and minimal thermal distortion compared with traditional arc welding processes. Furthermore, the ability to process out of vacuum and the easy robotic manipulation of fibre optically delivered 1?m wavelength laser beams, allow keyhole laser welding to process geometrically complex components. The widespread uptake of keyhole laser welding for the production of titanium alloy components in the aerospace industry has been limited by the stringent weld quality requirements. Producing welds with levels of subsurface weld metal porosity content meeting the required weld quality criteria has been the primary obstacle. Here, three techniques for controlling the levels of weld metal porosity when welding titanium alloys with Nd:YAG rod lasers have been developed. Characterisation of the welding processes using high speed photography and optical spectroscopy, have allowed an original scientific understanding of the effects these methods have on the keyhole, melt pool and vapour plume behaviour. Combining this with a thorough assessment of the weld qualities produced, has enabled the effects of these process behaviours on the formation of weld metal porosity to be determined. It was found that with the correct process parameters a directed gas jet and a dual focus laser welding condition can both be used to reduce the occurrence of keyhole collapse during Nd:YAG laser welding. The directed gas jet prevents the formation of a beam attenuating vapour plume and interacts with the molten metal to produce a stable welding condition, whereas the dual focus laser welding condition reduces fluctuations in the process due to an enlarged keyhole. When applied, both techniques reduced the occurrence of porosity in the weld metal of full penetration butt welds produced in titanium alloys. A modulated Nd:YAG laser output, with the correct waveform and modulation frequency, also reduced the occurrence of porosity in the weld metal compared with welds produced with a continuous-wave output. This was a result of an oscillating wave being set-up in the melt pool which manipulated the keyhole geometry and prevented instabilities in the process being established. In addition, the potential for welding titanium alloys to the required weld quality criteria with state-of-the-art Yb-fibre lasers has been assessed. It was found that the high power densities of suitably focussed laser beams with excellent beam quality, were capable of producing low-porosity full penetration butt welds in titanium alloys without the techniques required for laser beams with a lower beam quality. These new techniques for keyhole laser welding of titanium alloys will encourage the uptake of keyhole laser welding for producing near-net-shape high-performance aerospace components. The advantages offered by this joining technology include high productivity, low heat input and easy robotic automation.

Quantifying the effects of gap on the molten pool and porosity formation in laser butt welding - ScienceDirect

Porosity in Welding: What is it? And How to Prevent It

9 Possible Causes of Weld Metal Porosity

Reduced hot cracking susceptibility by controlling the fusion ratio in laser welding of dissimilar Al alloys joints, Journal of Materials Research

Shielded Metal Arc Welding (SMAW): Definition, How It Works, and Advantages

Welding Defects - Types, Causes and Remedies

Applied Sciences, Free Full-Text

What is the reason of porosity in welding? - Quora

Weld Porosity

Gas tungsten arc welding - Wikipedia

Recomendado para você

-

SCP-2082 - SCP Foundation25 abril 2025

SCP-2082 - SCP Foundation25 abril 2025 -

_scp-2951-10000-years.jpg) SCP-2951 - 10,000 Years from scp 10000 Watch Video25 abril 2025

SCP-2951 - 10,000 Years from scp 10000 Watch Video25 abril 2025 -

demo/docs/03_sparkLoad2StarRocks.md at master · StarRocks/demo25 abril 2025

-

SCP-2000 - Deus Ex Machina (SCP Animation)25 abril 2025

SCP-2000 - Deus Ex Machina (SCP Animation)25 abril 2025 -

Copyright © 2010 by the McGraw-Hill Companies, Inc. All rights25 abril 2025

Copyright © 2010 by the McGraw-Hill Companies, Inc. All rights25 abril 2025 -

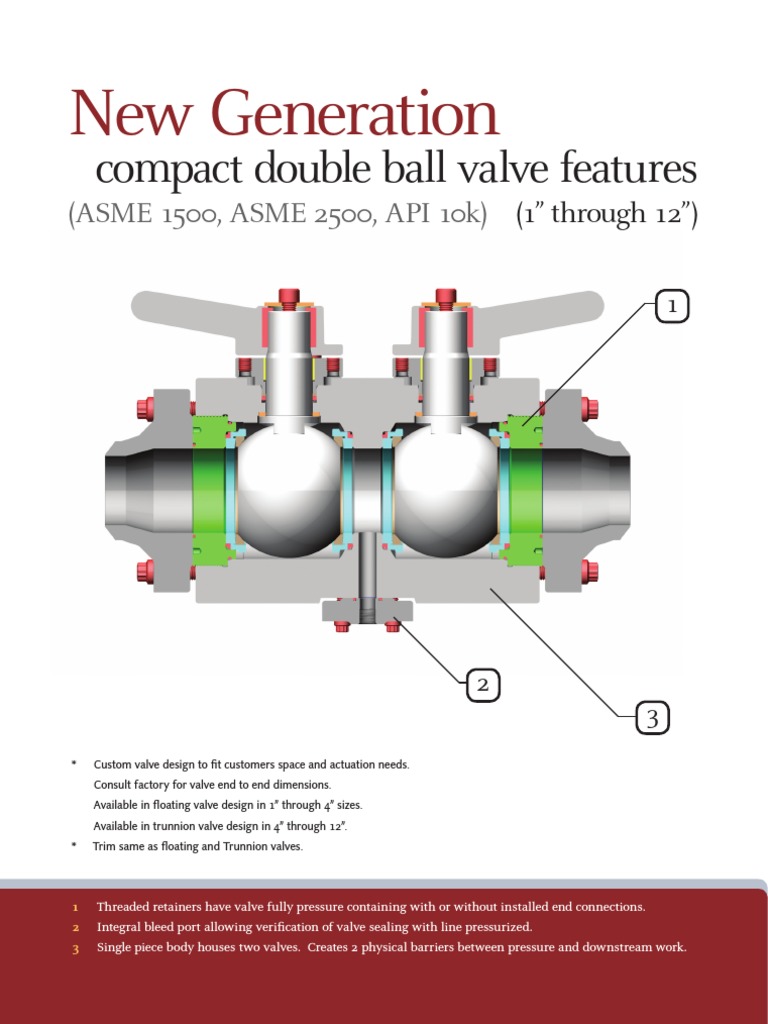

Double Ball Valve, PDF, Valve25 abril 2025

-

8 Advanced parallelization - Deep Learning with JAX25 abril 2025

8 Advanced parallelization - Deep Learning with JAX25 abril 2025 -

diris a40/a41 rs485 – profibus® dp - SOCOMEC Group25 abril 2025

diris a40/a41 rs485 – profibus® dp - SOCOMEC Group25 abril 2025 -

Muhammad Tahir - Executive Officer - TechTis Real Estate Marketing25 abril 2025

-

BUS 525: Managerial Economics Lecture 7 The Nature of Industry25 abril 2025

BUS 525: Managerial Economics Lecture 7 The Nature of Industry25 abril 2025

você pode gostar

-

IMAGENS DE DESENHOS PARA PINTAR E IMPRIMIR :: Avaré - Guia Avaré Guia Oficial da Cidade de Avaré25 abril 2025

IMAGENS DE DESENHOS PARA PINTAR E IMPRIMIR :: Avaré - Guia Avaré Guia Oficial da Cidade de Avaré25 abril 2025 -

Circuito Verão Sesc de Esportes encerra no próximo final de semana com show nacional da banda “Só Pra Contrariar” – Prefeitura de Torres/RS – Site oficial25 abril 2025

Circuito Verão Sesc de Esportes encerra no próximo final de semana com show nacional da banda “Só Pra Contrariar” – Prefeitura de Torres/RS – Site oficial25 abril 2025 -

![Emerald Randomizer] Didn't think my team would be too OP to not make the elite four boring. Apparently they can't handle a 160 attack magneton with pure power and choice band OHKOing](https://i.redd.it/qxhrk8mgak531.png) Emerald Randomizer] Didn't think my team would be too OP to not make the elite four boring. Apparently they can't handle a 160 attack magneton with pure power and choice band OHKOing25 abril 2025

Emerald Randomizer] Didn't think my team would be too OP to not make the elite four boring. Apparently they can't handle a 160 attack magneton with pure power and choice band OHKOing25 abril 2025 -

tensei kizoku no isekai boukenroku ep 8 - assistir online dublado25 abril 2025

tensei kizoku no isekai boukenroku ep 8 - assistir online dublado25 abril 2025 -

Tênis Mad Rats Skate Old School Areia Amarelo em Promoção na Americanas25 abril 2025

Tênis Mad Rats Skate Old School Areia Amarelo em Promoção na Americanas25 abril 2025 -

Anyone willing to do this trade? : r/adoptmeroblox25 abril 2025

Anyone willing to do this trade? : r/adoptmeroblox25 abril 2025 -

Forest Dance Academy taking a 'Journey to the Dark Side' with Disney villains for spring performance25 abril 2025

Forest Dance Academy taking a 'Journey to the Dark Side' with Disney villains for spring performance25 abril 2025 -

Explore the Best Tuskact4 Art25 abril 2025

Explore the Best Tuskact4 Art25 abril 2025 -

Ever After High Ashlynn Ella Praia Encantada - AliExpress25 abril 2025

Ever After High Ashlynn Ella Praia Encantada - AliExpress25 abril 2025 -

Xbox 20 Year Anniversary: How an American Video Game Empire Was Born - Bloomberg25 abril 2025

Xbox 20 Year Anniversary: How an American Video Game Empire Was Born - Bloomberg25 abril 2025